Get Your Power Semiconductor Devices to Market Faster

Demanding applications in automotive electrification and RF communications require wide bandgap semiconductor technology such as SiC and GaN along with the continued use of traditional silicon. SiC and GaN offer higher voltage operating frequencies, and higher temperatures with lower power loss compared to Si. Understanding the electrical performance of SiC and GaN will help enable a strong value proposition for their use in many emerging power applications. Get to market faster for your power semiconductor devices while minimizing device failures in the field.

I-V Characterization Measurements for Wide Bandgap Semiconductors

I-V Characterization

I-V Characterization

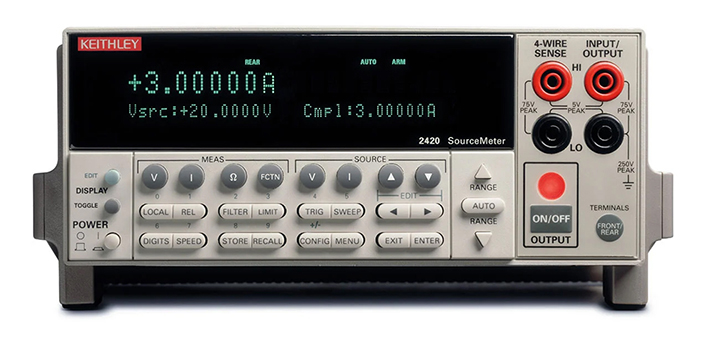

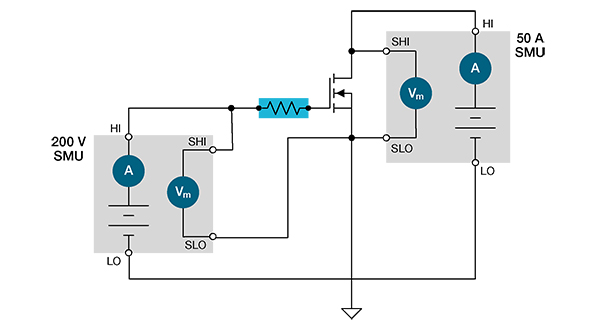

I-V Characterization is a fundamental method of understanding the current versus

voltage relationship of silicon, silicon carbide, and gallium nitride’s fundamental

properties. Using instruments like SMUs or parameter analyzers and appropriate

software, an I-V graphical curve is generated that is used to show the relationship

between the current flowing through an electronic device or circuit and the applied

voltage across its terminals. The most common set of I-V curves is the family of

curves.

DC I-V Characterization of MOSFET Devices Using KickStart Software

I-V Characterization

Test Across Wide Power Envelopes

Test Across Wide Power Envelopes

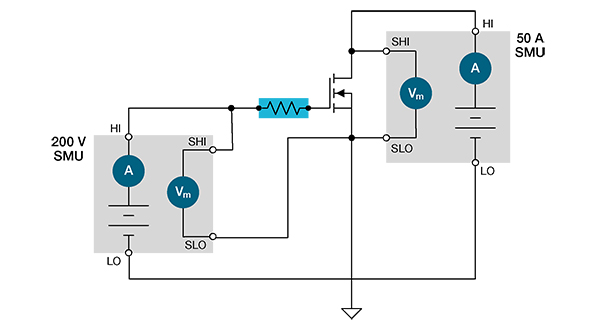

Characterizing SiC or GaN wafer- and packaged-part level devices for electrical

performance requires learning new techniques, such as utilizing higher power

instruments, dealing with the challenges of probing and making low level

measurements such as picoamp levels of leakage current in the presence of high

breakdown voltages. With wide bandgap semiconductors, it’s more common to be

sourcing voltages as high as 3000 V and currents up to 100 A. Just as important is

optimizing the testing system to reduce the amount of time it takes to change setups

for making ON-state, OFF-state, and capacitance measurements.

Solving Connection Challenges in On-Wafer Power Semiconductor Device Test Application Note

Breakdown Testing of Power Semi

Breakdown Testing of Power Semi

Devices

A device’s OFF-state breakdown voltage determines the maximum voltage that can

be applied to it. The primary withstand voltage of interest to power management

product designers is the breakdown voltage between drain and source of a MOSFET

or between the collector and emitter of an IGBT. For a MOSFET, the gate can be either

shorted or forced into a “hard” OFF state, such as by applying a negative voltage to

an n-type device or a positive voltage to a p-type device. This is a very simple test

that can be performed using one or two source measure unit (SMU) instruments.

Breakdown and Leakage Current Measurements on High Voltage Semiconductor

Devices

Connecting Instruments to Prober and

Connecting Instruments to Prober and

Test Fixtures

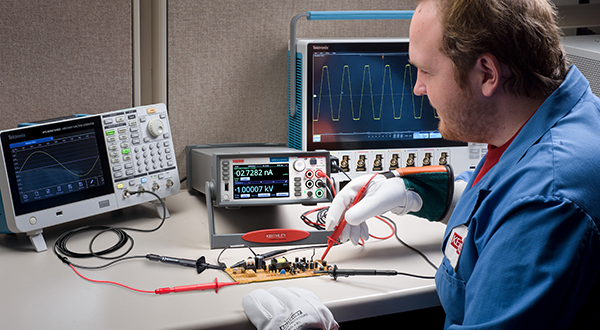

Connecting high power instruments to probe stations and test fixtures can be a

complicated task. Improper connections can often lead to measurement errors. The

8020 High Power Interface Panel provides a highly accurate, flexible, and easy to use

interface between Keithley SMUs and a variety of semiconductor probe stations or

custom test fixtures. The interface panel has six measurement pathways

accommodating 3 kV, 200 V, and 100 A measurements. You can configure five of the

pathways with a variety of output connector types to match your probe station. You

can configure four pathways with the optional bias tees. This provides high-voltage

C-V measurements on up to four pins of the device under test.

Safety First When Conducting High Power

Safety First When Conducting High Power

Tests

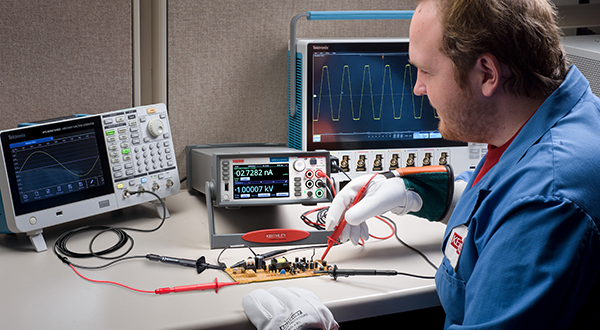

Safety should always be at the top of your mind when conducting high power tests

on wide bandgap semiconductors. Designing a safe and compliant test fixture for

the lab is not trivial. The 8010 High Power Device Test Fixture provides a safe, low

-noise, complete environment for testing a variety of packaged device types up to

3000 V and 100 A. The replaceable socket module test boards allow for a variety of

package types, including user-supplied socket types.

Automate Power Sequencing for I-V

Automate Power Sequencing for I-V

Characterization

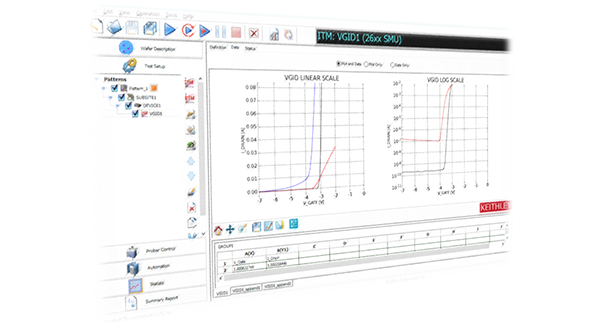

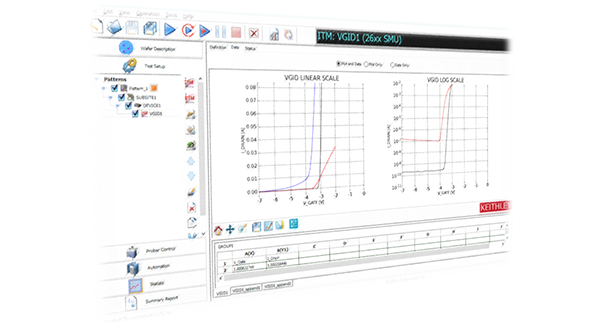

Save the trouble of programming your test with Keithley’s Automated

Characterization Suite (ACS) Software. ACS is a flexible, interactive software

test environment designed for device characterization, parametric test, reliability

test, and even simple functional tests. ACS supports a wide array of Keithley

instrumentation and systems, hardware configurations, and test settings. With

ACS, users are able to configure their instrumentation using the automated

hardware management tool and perform tests quickly without the need for

programming knowledge.

Power Sequence for GaN HEMT Characterization

Products

KALİBRASYON LABORATUVARI

KALİBRASYON LABORATUVARI

I-V Characterization

I-V Characterization Test Across Wide Power Envelopes

Test Across Wide Power Envelopes Breakdown Testing of Power Semi

Breakdown Testing of Power Semi Connecting Instruments to Prober and

Connecting Instruments to Prober and Safety First When Conducting High Power

Safety First When Conducting High Power Automate Power Sequencing for I-V

Automate Power Sequencing for I-V